Extremely fast 3D printer: 9157 cm³ per hour

The Solidator 8K is an ultra-fast industrial 3D printer based on next generation MSLA technology. It prints 20x faster than comparable standard FDM 3D printers and 10x faster than SLA printers or DLP 3D printers. The Solidator prints up to 9157 cm³ per hour at 200um layer thickness and 4197 cm³ per hour at 100um.

Video: 23 minutes per arm splint size 251 x 101 x 92 mm with Solidator Clear Resin. (time lapse) In total 6 arm splints in 2 hours 16 minutes.

Reliable, ultra-fast production of functional parts of any size

Solidator 8K and the Solidator Functional Resin are optimised for large industrial printed parts produced in record time. Solidator Functional Resin is much more tensile, strong, bend and scratch resistant than polyamide (PA12), yet offers sufficient impact strength and flexibility for snap fit designs.

Size: 68 x 51 x 13 mm

Parts per print: 20

Resin: Solidator Functional R001

XY: 43 micron Z: 200 micron

Size: 20 x 22 x 28 mm

Parts per print: 126

Resin: Solidator Functional R011

XY: 43 micron Z: 100 micron

Size: 29 x 24 x 65 mm

Parts per print: 60

Resin: Solidator Functional R011

XY: 43 micron Z: 100 micron

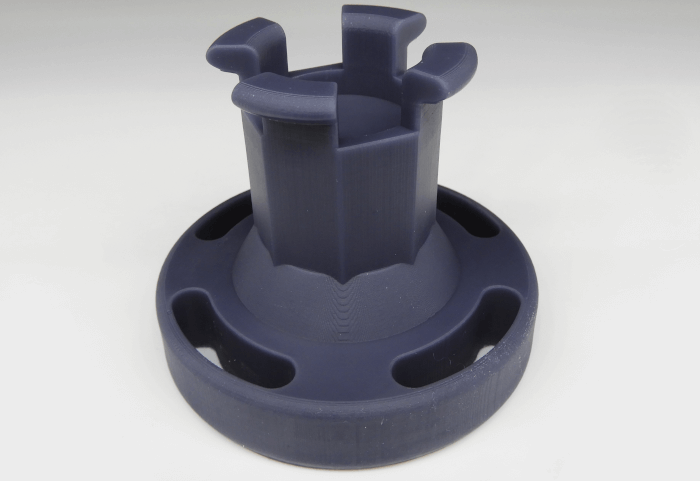

Size: 64 x 64 x 47 mm

Parts per print: 14

Resin: Solidator Functional R011

XY: 43 micron Z: 100 micron

Size: 60 x 60 x 50 mm

Parts per print: 15

Resin: Solidator Functional R011

XY: 43 micron Z: 100 micron

Size: 99.2 x 95.7 x 35.5 mm

Parts per print: 6

Resin: Solidator Functional R011

XY: 43 micron Z: 100 micron

Size: 120 x 40 x 120 mm

Parts per print: 10

Resin: Solidator Functional R011

XY: 43 micron Z: 100 micron

Extremely large Build Volume - over 24 litres

The Solidator is not only fast, but can also print very large objects up to 330 x 185 x 400 mm. It is also possible to print many small models at once. This makes it ideal for industrial production of small series, prototypes and individual parts.

Size: 101 x 92 x 251 mm

Parts per print: 6

Resin: Solidator Functional R001

XY: 43 micron Z: 200 micron

Size: 255 x 170 x 71 mm

Parts per print: 1

Resin: Solidator Functional R011

XY: 43 micron Z: 200 micron

Size: 155 x 155 x 344 mm

Parts per print: 2

Resin: Solidator Orange R001

XY: 43 micron Z: 200 micron

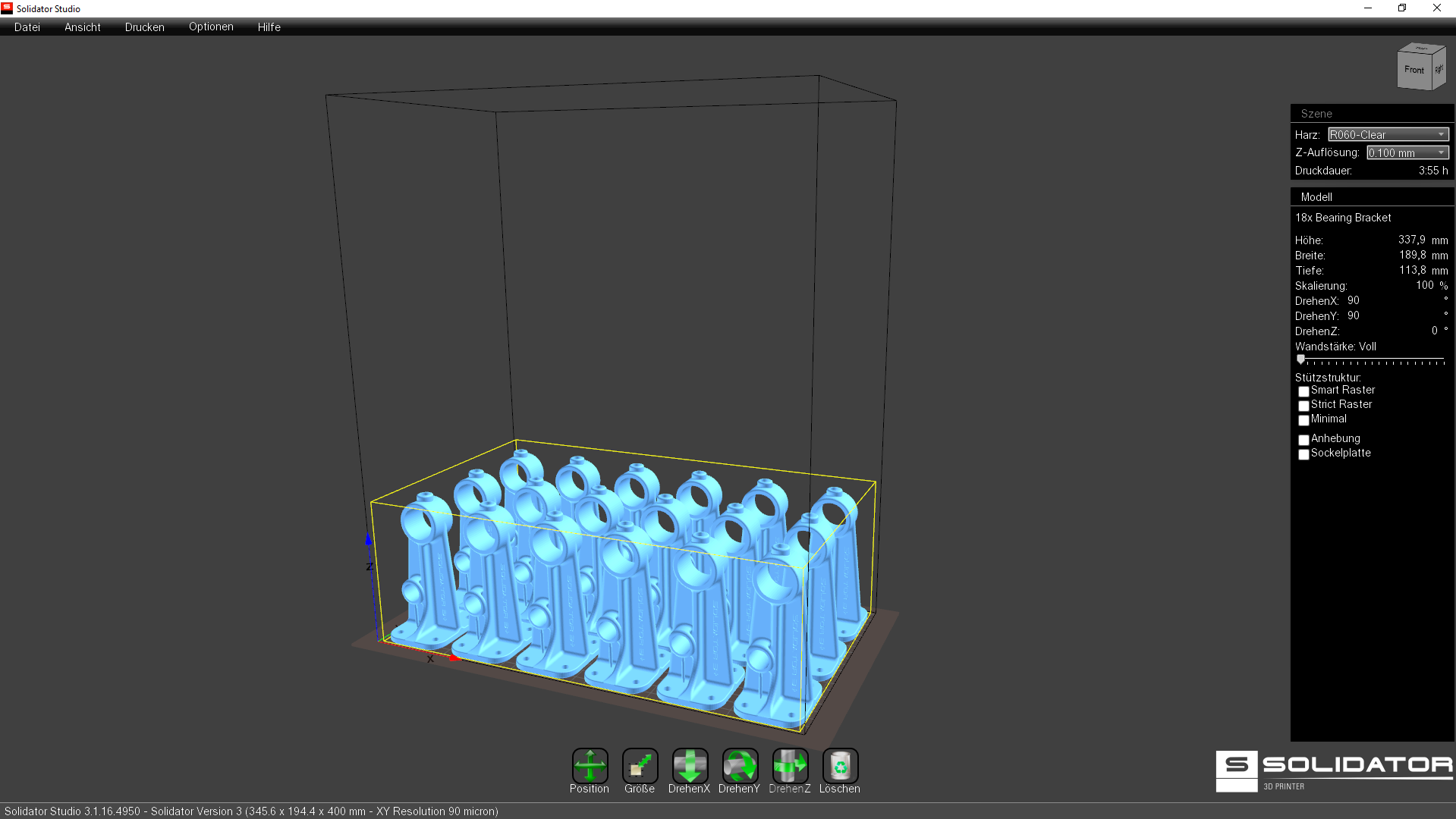

Size: 131.7 x 56.4 x 398.7 mm

Parts per print: 6

Resin: Solidator Clear R060

XY: 43 micron Z: 100 micron

Size: 131.7 x 56.4 x 398.7 mm

Parts per print: 6

Resin: Solidator Functional R011

XY: 43 micron Z: 100 micron

Size: 131.7 x 56.4 x 398.7 mm

Parts per print: 6

Resin: Solidator White R051

XY: 43 micron Z: 100 micron

Size: 233.6 x 185 x 231.7 mm

Parts per print: 1

Resin: Solidator White R051

XY: 43 micron Z: 100 micron

Size: 233.6 x 185 x 231.7 mm

Parts per print: 1

Resin: Solidator Functional R011

XY: 43 micron Z: 100 micron

Advantages of our 3D printing process with large 3D printer

High throughput using MSLA resin 3D printing

The mask stereolithography (MSLA) 3D printing process used provides the highest throughput, because each layer is cured at once via a mask exposure - a time-consuming point-by-point processing of the build space as with SLA 3D printers, industrial FDM 3D printers and SLS 3D printers is not necessary. The large build space or footprint makes this advantage particularly large. The Solidator is the largest industrial 3D printer that does without the disadvantageous perforated printing plate.

Video: 60 brackets measuring 29 x 35 x 65 mm printed in 1 minute 32 seconds per piece with Solidator Functional Resin. (time lapse)

Very high surface quality

The surface quality of MSLA 3D printers is comparable to laser-based SLA 3D printers and far better than SLS and FDM technology. In fact, one of the main reasons for using an LCD as a mask instead of a DLP chip is the higher native resolution. The LCD allows higher native resolutions than DLP systems on DLP printers.

Synthetic resins for functional parts

The printing process is particularly well suited for rigid materials. With the materials specially produced for the Solidator 8K industrial 3D printer, it is also possible to produce very large functional parts cost- and time-efficiently. The Solidator is a large industrial 3D printer that comes with its own range of materials.

Optimised material consumption

Another advantage is that there is no need for a material reservoir the size of a building space, as is the case with SLA 3D printers or SLS 3D printers. Instead, a low filling level of 800 ml is sufficient in the material tank. Only material that has actually been used is constantly refilled via an automatic refill system. The reduction of the material tank volume results in high cost savings. The large material tank is often a disadvantage of a classic SLA 3D printer with a large build volume, because in the case of the Solidator 8K, this would already contain over 24 litres of material. Resin 3D printers that work classically according to the top-down stereolithography process still need this material stock today and for this reason are not an economical solution for most users. Industrial 3D printers with synthetic resin that work according to the bottom-up method have clear advantages here.

Lower acquisition costs than SLS 3D printers and DLP printers

By using LCD mask technology (MSLA), the acquisition cost of the system can be reduced compared to DLP printers while exceeding the resolution.

Resins for high-speed 3D printing & high precision

The Solidator materials have been specially developed for high-speed, high-volume 3D printing.

In addition, we offer materials from our Material partners BASF and Henkel for which Solidator 8K has been validated.

GPU-accelerated slicer with automatic support structure generation

Solidator Studio is the professional all-in-one software for preparing models, creating support structures and GPU-accelerated slice calculation. Print settings for our materials are already stored in the software for optimal 3D printing results. This allows you to quickly and easily prepare 3D models to print on the Solidator 8K. Solidator Studio supports Windows 7/8/10/11 operating systems.

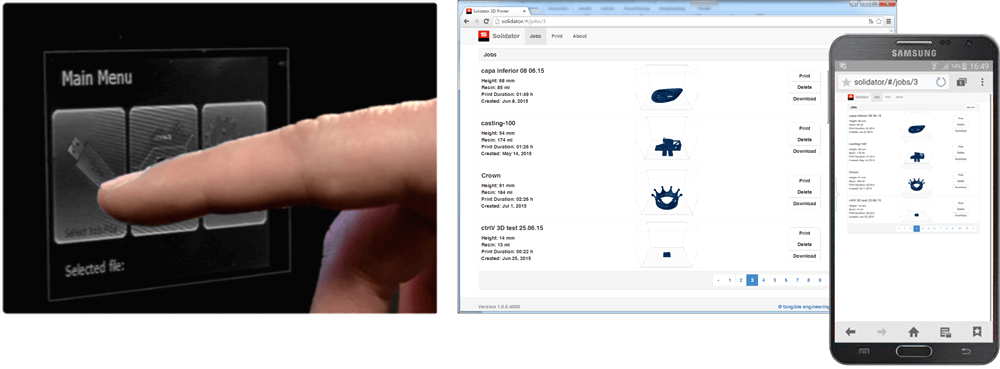

Modern touch-controlled stand-alone 3D printing

The Solidator has an integrated touch-enabled computer for printing without cables. You don't need a PC next to the resin printer. Transfer your print files to the 3D printer via USB, Lan or W-Lan. The modern HTML5 web interface helps you to organise and monitor your prints. This means that the industrial resin printer does not have to be set up directly at your workplace.

True Plug & Play - immediately printable

Fully assembled - Factory setting: Z-Calibration - Fine-tuned settings for each of our resins. Solidator offers a complete ecosystem to ensure you get the best possible results: Hardware, software, resin and support from a single source.

Trust of our customers from the industry

From the first prototype to large-scale production, being able to get support, materials and parts in time is crucial.

Technical specification

If you would like to learn more about the technical details of our industrial resin 3D printers, please click on the page Hardware to see a breakdown of features and specifications. This will give you all the information you need to make an informed decision about our 3D printer.

More than 132 billion voxels 0.043 mm x 0.043 mm x 0.1 mm Voxel size

on a Large Build Volume: 330 x 185 x 400 mm

© 2024 tangible engineering GmbH. All rights reserved. | About us & Imprint

German

German English

English Spanish

Spanish French

French Italian

Italian Swedish

Swedish Finnish

Finnish Portuguese

Portuguese Indonesian

Indonesian